The Myth of “No Vent Cap Needed” on PVC Vent Pipes

Why skipping a proper vent termination is risky — and how to do it right

A recent discussion on the r/Roofing subreddit (“Trying to figure out if this needs to stay the way it …”) revealed two faulty beliefs:

-

“We don’t need a vent cap on this PVC stack — it’ll just vent normally.”

-

“If you use a cap, any cap is fine — just slap something on it.”

Both of these positions deserve a deeper look — because a vent termination is about airflow control, weather protection, and building longevity.

Why the “no vent cap” idea is flawed

Let’s take the first assumption: “I don’t need a vent cap on the PVC vent pipe”. Here’s why that is problematic.

1. Uncontrolled airflow & back-draft risk

A vent stack is designed to allow gases (for example drainage-system venting or appliance exhaust) to escape to atmosphere smoothly. Without a proper termination, the open top of a PVC pipe essentially becomes a straight pipe into the sky. That means:

-

In windy conditions, you can get eddy currents or vortices at the mouth of the pipe, causing turbulent inflow when you want outflow.

-

When the pipe top is simply open, a gust hitting the rim can induce a slight suction or reversal of flow (Bernoulli principle: faster moving air → lower pressure), potentially pulling air into the vent rather than letting gases escape.

-

Rain, snow or debris can enter freely, undermining the system’s function and leading to blockages or moisture intrusion.

From an aerodynamic perspective: if a pipe opening is flush with the ambient flow (i.e., exposed to the wind), there is minimal guidance of the flow, and the chance of flow reversal or unwanted mixing is far higher. A proper termination introduces geometry that encourages stable, unidirectional flow, deterring adverse wind effects.

2. Weather and pest intrusion

An uncapped vent is an inviting portal for:

-

Rain/snow entry, which can cause corrosion or freeze-thaw damage inside the pipe or the connected system.

-

Leaves, debris or bird nests that eventually restrict airflow.

-

Pests and insects that can build nests, block vents or introduce unwanted odors.

Thus, skipping a vent cap isn’t simply “OK because it will vent anyway”. It’s a risk to performance and longevity.

3. Code and manufacturer considerations

Many building codes and appliance manufacturers expect that terminations are protected, screened or otherwise designed to prevent external intrusion. Omitting a cap may not explicitly be forbidden in every locality—but it often fails to meet best-practice, and may void warranties or create inspection issues.

Why “any cap will do” is also a poor assumption

Now the second faulty assumption: “If I install a vent cap, it doesn’t matter which one.” Not true—because the cap geometry matters from an aerodynamic and functional perspective.

Improper cap geometry can degrade flow

Consider what happens if you pick a cheap or poorly designed cap:

-

The opening may be too small, introducing flow restriction. According to basic fluid-dynamics (continuity equation), a smaller area means higher velocity for the same volumetric flow; higher velocity → greater frictional losses → reduced effective venting.

-

The cap may cause turbulence or swirling at the outlet, which increases energy losses, flow separation and possibly back-pressure. You ideally want smooth flow transition from the pipe to the atmosphere.

-

Some caps may have internal vanes or baffles that trap debris or condense moisture. If moisture collects, it can drip back into the pipe or corrode the fitting.

Cap placement matters

-

The cap should be installed vertically upward from the pipe stack (with minimal offset) so the flow has the shortest path to atmosphere. Sharp turns or side exits increase losses.

-

The termination should project enough above the roof or flashings to avoid recirculation from roof-edge winds or eddies created by nearby structures (chimneys, dormers, parapets).

-

Any screen or mesh included must be sized so it does not degrade flow significantly.

From an aerodynamic lens

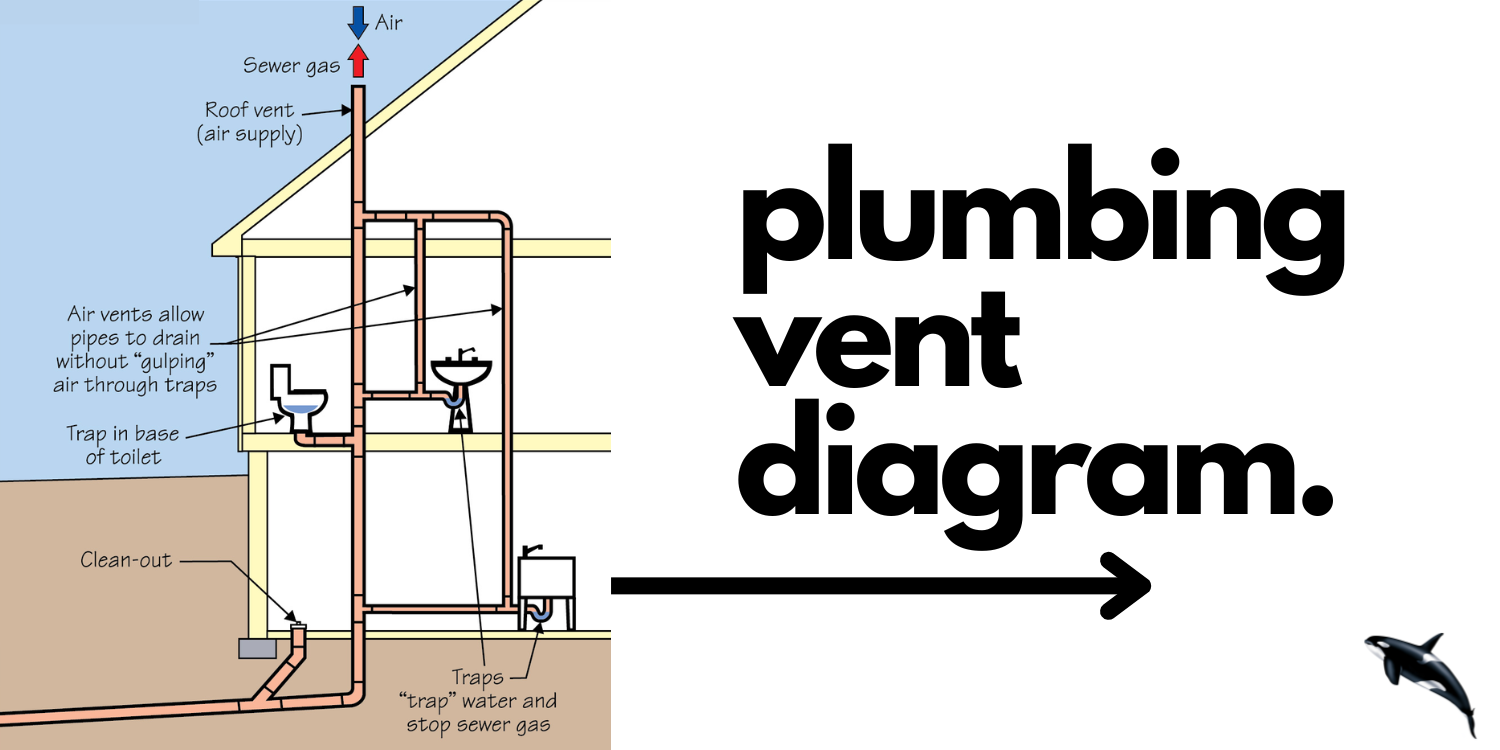

Here’s a simple figure illustrating how flow enters the open atmosphere from a pipe termination:

You can see how a well-designed termination allows flow to peel off smoothly, whereas an unprotected or poorly designed opening invites recirculation zones, reverse flow and instability.

Recommended product and why it fits

Given the above, you want a vent termination that:

-

Protects against weather/pests,

-

Minimizes flow losses,

-

Provides a stable outlet geometry,

-

Meets common building-industry expectations.

One good option: the product listed on Amazon here: termination stainless 90 Degrees Installation.

Here is why I recommend it:

-

It’s made of stainless steel, so it resists corrosion, which is important for longevity.

-

The 90° orientation ensures the cap stands upright and the outlet faces upward, making it less vulnerable to rain/snow intrusion while still allowing smooth discharge.

-

The design appears to provide a mesh screen (or provision for one), which helps keep out insects/rodents but doesn’t overly restrict airflow if sized properly.

-

The geometry looks compact and robust, aligning with best-practice for termination height and flow direction (vertical upward) rather than a horizontal tee or low-profile cap.

If installed correctly (i.e., securely sealed/flashed at the roof, projecting above the roof surface, and without unnecessary elbows or turns below), this kind of termination offers both wind- and weather-resilience and minimal flow resistance.

Installation “science-check” list

Here’s a scientific check-list to ensure your vent stack termination works as intended:

-

Height above roof surface: The vent outlet should project sufficiently above the roof plane or any adjacent obstruction so that the outlet flow does not immediately meet turbulent roof‐shear layer.

-

Vertical flow path: A straight vertical rise is preferred to maintain laminar or smoothly mixed turbulent flow exiting the pipe — fewer bends = fewer losses.

-

Outlet cross-section: Ensure the cap’s outlet matches or slightly exceeds the pipe’s internal cross-section (for a 4″ PVC, area ~12.6 in²). If the cap restricts it significantly, you’ll reduce volumetric flow and raise internal pressures.

-

Weather protection/mesh screen: Good to include a corrosion-resistant mesh, but check its open area versus blockage. A mesh with only 30% open area will significantly increase exit velocity and friction losses (per DarcyWeisbach/drag‐loss principles).

-

Sealing and flashing: Ensure no leaks around the roof penetration; moisture ingress leads to structural issues or mold.

-

Wind effects: If the vent is too low or adjacent to roof edges/dormers, wind‐induced vortices can reduce performance. A proper cap and elevation mitigate this.

Why a “Tee” or sideways termination is usually inferior

Returning to the rooftop scenario discussed, some may propose using a 3-way “Tee” termination (i.e., a sideways outlet) or just attaching a low-profile cap to the side of the pipe. These layouts carry multiple aerodynamic and functional risks:

-

Sideways outlets can suffer wind clipping (wind blowing across the opening creates lower pressure inside the pipe, potentially drawing in air rather than allowing exhaust).

-

A Tee introduces an abrupt change in flow direction — from vertical pipe → horizontal branch → vertical cap — each direction change adds loss, turbulence, and risk of condensation/intrusion.

-

Maintenance becomes harder: debris can collect in the horizontal branch, water can pool/enter the side opening, and pests can more easily nest.

-

From a code or longevity perspective, these layouts are less robust compared to a straight riser with a proper cap.

Therefore, the correct path is to treat the vent stack as a vertical “chimney” for the discharge (or intake) of air/gases, not as a side-branch or unprotected opening.

Final thoughts

Putting it all together:

-

Skipping a vent cap might seem simple, but it opens the system to uncontrolled airflow, weather intrusion and performance degradation.

-

Installing a cap is good — but the wrong cap (or the wrong orientation) can compromise flow efficiency and safety.

-

Use a termination that ensures upward, unimpeded flow, good weather protection, minimal curvature, and proper flashing.

-

A product like the recommended stainless 90° termination offers these features and aligns with aerodynamic and building‐science principles.

-

Always verify local code, the specifications of the pipe system you’re venting, and the manufacturer’s guidance for the appliance or system involved.